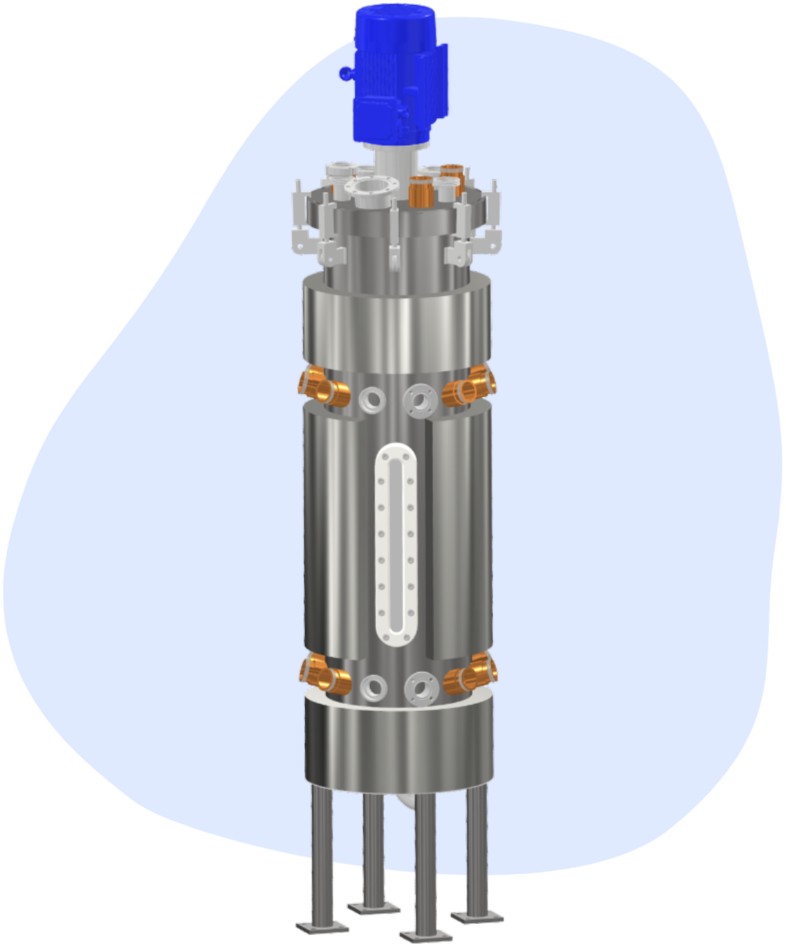

Our pilot-scale bioreactors are designed to serve as the critical bridge between scientific possibility and commercial reality. These bioreactors are pivotal in facilitating the scale-up processes, accommodating volumes ranging from 200 to 5000 liters. They are engineered to offer the perfect amalgamation of precise control and substantial capacity, ensuring a seamless and efficient transition from lab-scale experimentation to larger-scale production.

With robust design and intuitive interfaces, our pilot-scale bioreactors are the ideal choice for researchers and industry professionals aiming to bring groundbreaking bioprocessing discoveries to market with efficiency and reliability.

Benefits at a glance

Versatile scale-up capability

Designed to transition processes seamlessly from small-scale experiments to larger production scales, ensuring consistency and reliability in bioprocessing.

Advanced control systems

Equipped with sophisticated monitoring technology, AUXO V® bioreactors allow for precise manipulation of environmental parameters, ensuring optimal growth conditions and process reproducibility.

Highly customizable design

Features modular components and flexible configurations, enabling customization to specific process needs. This adaptability is key for diverse applications.

Purpose-driven configurations

Modular design

Easy to design configurations to adapt to varying process requirements, enhancing scalability and experimentation versatility

Extensive integration capabilities

Designed to fit into existing workflows with customizable input/output options, simplifying integration with other equipment

Customizable software

Software and interfaces can be tailored for specific user requirements, improving process control and data management

Tailored equipment

Long-lasting materials

Made with durable materials suitable for demanding bioprocesses, ensuring long-term reliability and safety

Advanced sensor technology

High-quality sensors provide accurate, real-time monitoring, ensuring optimal growth conditions and process efficiency

Impellers

Optimized for different organisms in line with shear stress of respective cell type

Optimized running costs

Easy-clean systems

Features such as self-cleaning mechanisms or easy disassembly reduce downtime and labor costs associated with maintenance. All pilot-scale bioreactors can be provided with a CIP/SIP system upon request

Diagnostic and alert systems

Automated monitoring identifies potential issues early, facilitating preventive maintenance and reducing unexpected repair costs

Component-based design

Simplifies replacement and upgrades of parts without extensive system downtime, ensuring continuous operation with minimal maintenance interruptions

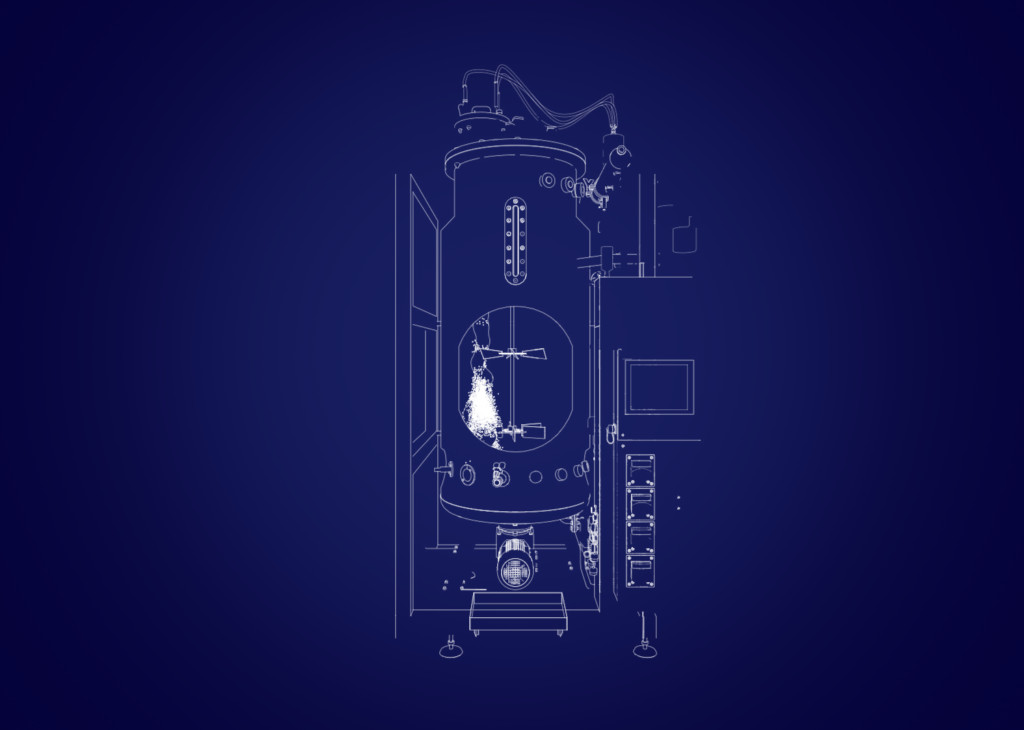

Look inside

We develop and produce advanced technology to make the future of nutrition and health an affordable reality.