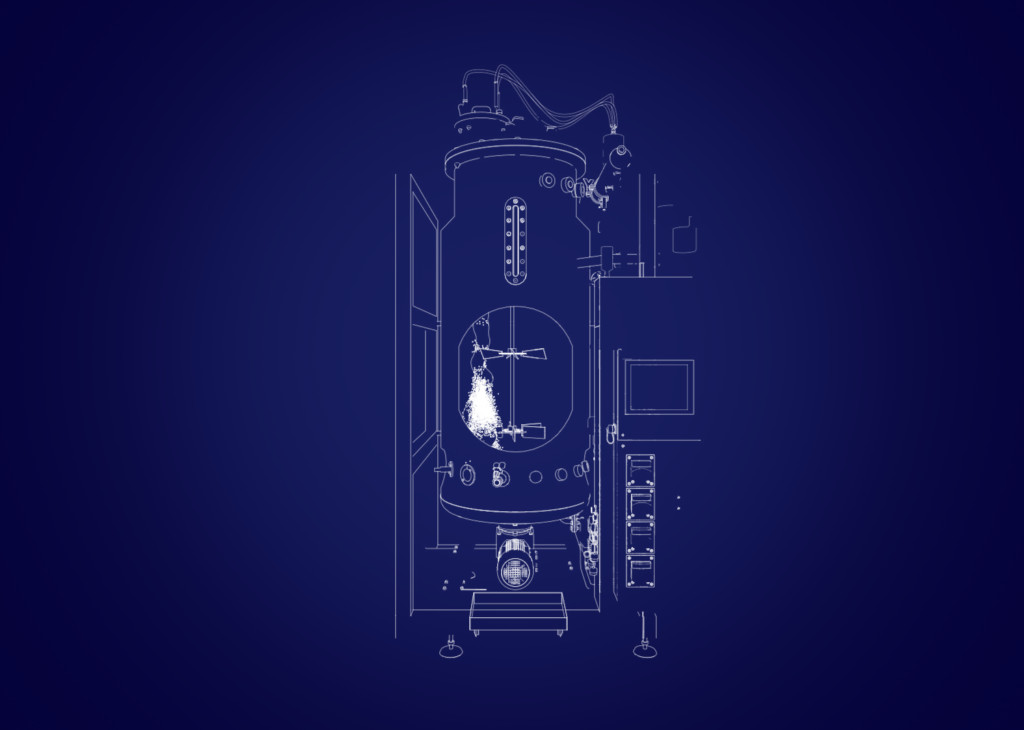

Designed for precision and versatility, our benchtop AUXO V® bioreactors (from 1L to 200L) offer unparalleled control for research and development.

Engineered for both seasoned researchers and pioneering scientists, they facilitate breakthroughs by combining reliability with intuitive operation. Our bioreactors are tailored to empower bioprocessing innovation, allowing for seamless scalability and flexibility in various research settings.

Our benchtop bioreactors are the ideal tool for those seeking to push the boundaries of biotechnology, providing a robust platform for experimentation and discovery.

Benefits at a glance

Precision control environment

Our benchtop bioreactors offer highly accurate control of the culture conditions like temperature, pH, and oxygen levels, crucial for small-scale experiments and process development.

Compact and efficient design

Optimized for limited space in laboratory settings, AUXO V® bioreactors are designed for efficiency and ease of use, making them ideal for research and educational purposes.

Advanced data monitoring

Equipped with sophisticated sensors and data analysis tools, AUXO V® bioreactors provide detailed insights into biological processes, facilitating rapid experimentation and optimization.

Designed to fit your needs…

The benchtop AUXO V® bioreactors can be available in different configurations to offer customizable, cost-effective solutions with short delivery times and to meet diverse research needs efficiently.

Cell culture

Microbial culture

Purpose-based

Product specifications of our benchtop bioreactors:

- Available sizes 1L, 2L, 3L, 5L, 7L, 15L, 50L, 100L.

- For larger sizes visit: pilot-scale bioreactors (from 200L to 5000L) or industrial-scale bioreactors (>5000L)

- Either glass (small vessels) or stainless steel (from 15L)

- Multi-use capability allows for optimized cost distribution

- Wide range of optimized impeller blades including Rushton, marine, pitched-blade, etc.

- All small vessels are autoclavable. Sterilization systems (CIP/SIP) available for larger vessels.

- Customization based on application. Configure your biomachine

- Hamilton DO/O2 digital sensor. 7 – 100% (0.1% resolution)

- Hamilton pH digital sensor. 5 – 8 (0.1 resolution)

- Temperature Pt 100 sensor. 0 – 100°C (0.1°C resolution)

- Other sensors: foam, glucose, lactate, more available upon request

- High precision fluid pumps (Watson Marlow technology), 6-8 peristaltic pumps depending on reactor size 114ST, 0-600RPM). Connection for external pumps available

- Industrial Programmable Logic Controller (PLC) from Siemens

- Touch panel 10’’ / Touch screen / Removable

- USB 2.0, Industrial Ethernet

- 6-8 pumps depending on reactor size (114ST, 0-600RPM), connection for external pumps available

- 4 gas control valves for compressed air, oxygen, CO2 and N2

- Pre-configured cultivation programs

- 3 layers with increasing level of detail and complexity (from no experience in bioprocessing to in-depth bioprocessing knowledge)

- Web-based remote monitoring

Glass or steel?

We offer the best materials for your bioprocessing focusing on multi-use materials that can be easily maintained in a sustainable way.

Glass

Small-scale bioreactors (1-15L) with durable glass vessels, ideal for precise control in research and development, featuring easy observation.

Steel

Larger bioreactors (15-200L) with robust stainless steel vessels, designed for scalability and high-volume processing, ensuring longevity and reliability.

Everything under control …

A control unit like never before. Three interfaces included to ensure usability for operator groups.

Look inside

We develop and produce advanced technology to make the future of nutrition and health an affordable reality.